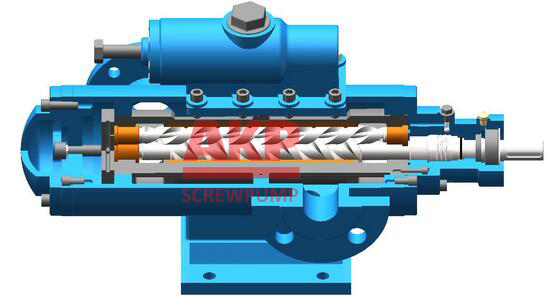

Twin Screw Pump 2500 series

Basic Info

Model No.: 2500 series

Product Description

Twin-screw pump products are divided into two categories: single suction twin screw pump and double suction twin screw pump. This series of products have special screw thread and special structure matching. It is widely used in various industries, such as oil, chemical, metallurgy, steel, power, ship, pharmaceutical, food, building materials, etc., the application of many media, the wide range of transportation and the complex application conditions are incomparable to other pump products. These characteristics also make the series pumps have potential application and development prospects.

Prolongation of life

Prolong the service life of the single screw pump:

First, reduce the number of times for the screw pump to stop. For the sand laden well, clear water or sand free liquid should be used before replacing the pump body and the well fluid in the tubing. Prevent sand burying tubing (gas anchor) and sand sticking.

Two. Popularizing the technology of frequency conversion control to solve the problem that the speed of the oil Sucker Rod and the determination of the torque can be reduced. It can completely realize real-time, automatic, continuous, slow release reversal torque, reduce the sudden increase of torque and shear force during the sudden start of the motor, avoid reversing and reduce the breaking and stripping probability of the sucker rod. The pump cycle is long, but it is only used as a soft start device. In view of the complexity of the geological conditions at sea, the gas, water and oil content of the screw pump are different under different pressure differences. It is suggested that the rotating speed of all the screw pump wells which install the inverter can be adjusted to (power frequency 50 Hz, drive head 5: 1) 186 r/ min using frequency converter. By adjusting the frequency of speed control, through the test to select the maximum benefit point, greatly reducing labor intensity.

Characteristic advantages

1. The conveying liquid is stable, no pulsation,no agitation, little vibration and low noise.

2, self-priming performance is very strong, multiphase, gas rate is not higher than 80%, the sediment concentration is less than 500g/m3.

3, the external bearing structure, the use of independent lubrication, can transport all kinds of non lubricating media.

4, the use of synchronous gear drive, the two rotor contact, even if a short time idle.

5. The pump body has a heating sleeve, which can convey various low viscosity or high viscosity media with clean or solid small particles (the diameter of the particles is less than 0.12-0.2mm).

6, the correct selection of materials, and even transport a lot of corrosive media.

7, double suction structure, there is no axial force on the rotor.

8. Shaft ends adopt mechanical seals or bellows mechanical seals. They have long service life, less leakage and wide application scope.

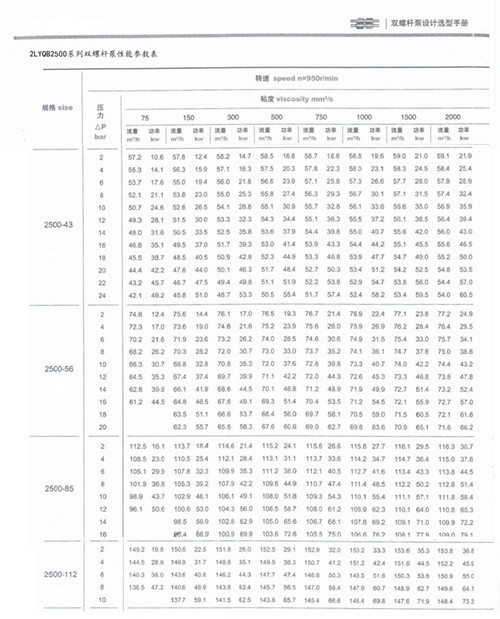

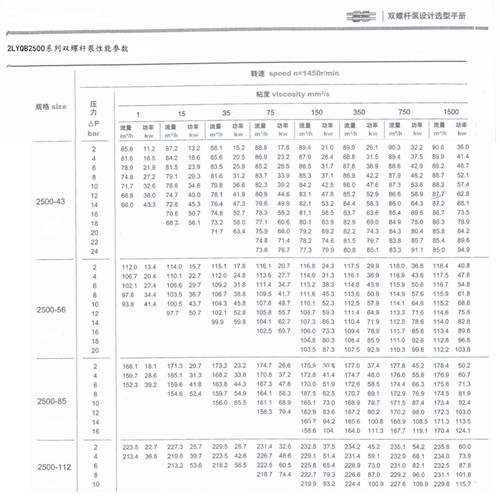

Product Categories : Twin Screw Pump > 2LYQB2500series Twin Screw Pump